The Pit River (Ahjoomah) is the largest river in northeastern California; its watershed is 4,324 square miles. The mainstem Pit flows in a southwesterly direction (but flows straight north and straight west in some sections of the Big Bend!) through valleys and basalt canyons to Shasta Lake (an artificial reservoir that submerged thousands of acres of habitat that was stolen from the indigenous tribes).

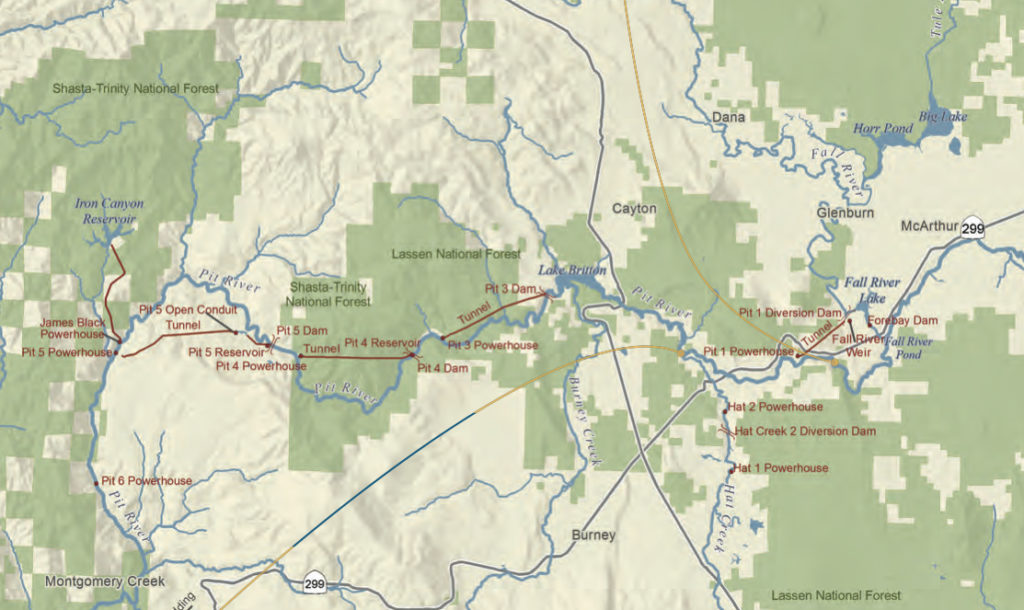

The Pit River is heavily dammed for hydropower, and Pacific Gas & Electric (PG&E) holds several operating licenses in its system. The Pit projects are numbered by their age and upstream to downstream. The most upstream project, Pit 1, began construction in 1920. From 1923 to 1926, licenses were issued to construct Pit 3 and Pit 4 developments. In 1942, when PG&E renewed the license for Pit 3 and Pit 4, it also received authorization to construct Pit 5. Pit 6 was completed in 1965, the same year the James Black powerhouse was finished.

Major Dams Effecting Pit River:

1. Pit 1 Diversion Dam (on Fall River, 1920)

2. Fall River Weir (low dam regulating flow & raising water level upstream)

3. Forebay Dam (on Fall River)

4. Hat 1 Diversion Dam (on Hat Creek)

5. Hat 2 Diversion Dam (on Hat Creek)

6. Pit 3 Diversion Dam (on Pit River, forms Lake Britton, 1925)

7. Pit 4 Diversion Dam (on Pit River, forms Pit 4 Reservoir, 1955)

8. Pit 5 Diversion Dam (on Pit River, forms Pit 5 Reservoir & Tunnel Reservoir, 1944)

9. Iron Canyon Dam (on Iron Canyon Creek, McCloud river water + several creeks, 1965)

10. Pit 6 Diversion Dam (on Pit River, forms Pit 6 Reservoir, 1965)

11. Pit 7 Diversion Dam (on Pit River, forms Pit 7 Reservoir, 1965)

12. Shasta Dam (on Sacramento River, below confluence of Pit + 3 other rivers, 1937)

Summary of Water Rights and Water Purchases:

The Pit River has been used for water supply and hydroelectric generation since the early 1900s. Water uses associated with the projects consist of non-consumptive storage and power generation; however, Pacific Gas and Electric Company also operates the project to provide other beneficial uses such as recreation, aquatic and wildlife habitat, and as much profit as they can squeeze out of the river’s energy.

Pacific Gas and Electric Company relies upon a combination of licensed and riparian water rights for power generation purposes at the Pit 3, Pit 4, and Pit 5 Powerhouses. The company relies upon riparian water rights for domestic purposes, incidental irrigation, and fire protection at Camp Shasta, Camp Britton, and the Pit 5 Powerhouse.

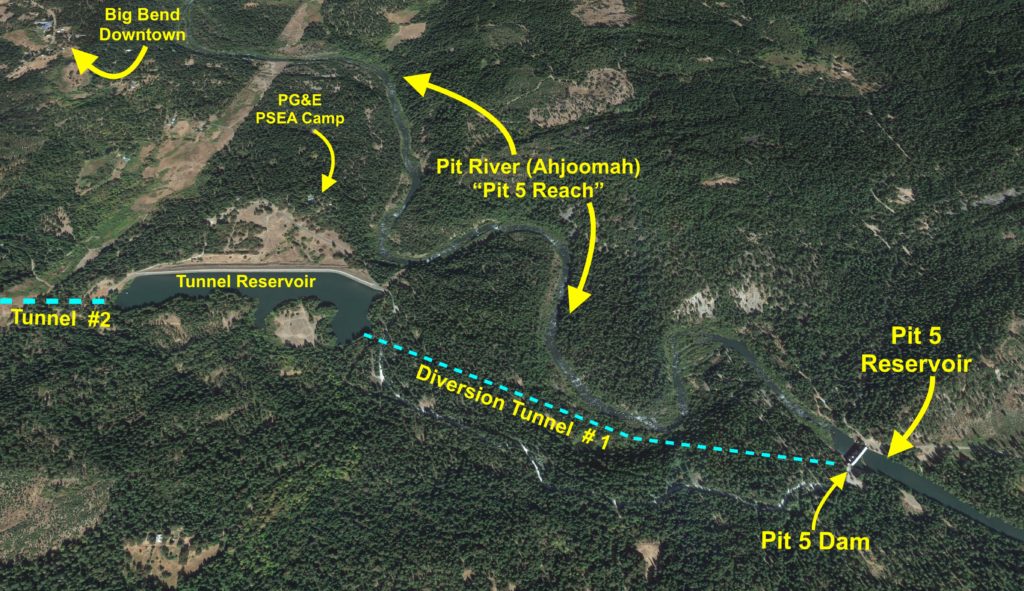

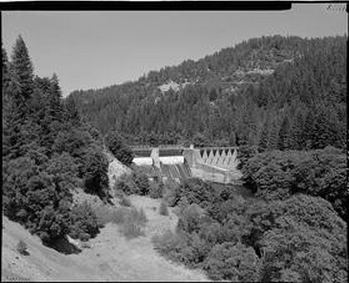

Two reservoirs (one called the “Pit 5 Reservoir” and the other called the “Open Conduit Reservoir”) provide river water storage for the Pit 5 Powerhouse. The Pit 5 Reservoir (just above the dam, as seen in the picture below) has a usable storage capacity of 314 Acre-Feet, or 102,317,214 gallons (1 AF = 325,851 gallons), a surface area of 32 acres, and is created by a 67-foot high concrete gravity dam (Pit 5 Dam) with a 340-foot crest length. The Open Conduit Reservoir (also known as Tunnel Reservoir) has a usable storage capacity of 1,044 AF (340,188,444 gallons), a surface area of 48 acres and is created by a 71-foot high earth-filled dam (giant berm visible from Hagen Flat Road) with a 2,964-foot crest length (shown in satellite image in the third picture below).

In the pictures above and below, the flotsam (floating debris) catch system can be seen just above the dam (it looks like a curving floating tube with plants growing on it). This floating barrier has submerged nets and it prevents most river debris from entering Tunnel #1. (Debris such as tree branches, logs, lost boats, innertubes, toys, flip-flops, kayak paddles, or other large floating human litter) There is also a grate at the tunnel entrance (partially visible in the picture below), which acts as a second trap for floating debris that gets past the flotsam catch. (This grate is periodically cleared of the caught debris by a modified excavator on a fixed track with a special attachment on its arm that combs and clears the grates).

Pit 5 Diversion Dam to Pit 5 Powerhouse:

Water is diverted from the Pit 5 Reservoir to Tunnel #1, which is a 19-foot diameter, horseshoe and circular tunnel that can discharge up to 3,400 CFS to the Open Conduit Reservoir (also known as Tunnel Reservoir). The Open Conduit Reservoir is formed by the Pit 5 Open Conduit Dam, and serves as a 3,124-foot conduit connecting Tunnel No. 1 to Tunnel No. 2. The outlet works for the Open Conduit Reservoir is the intake for Tunnel No. 2, which carries water through a 19-foot diameter, concrete lined tunnel further across the valley, cutting the corner of the big bend in the river.

(AKA “the “Pit 5 Reach”) with only about 13% of its natural flow –

A bad idea and an environmental crime started over 80 years ago.

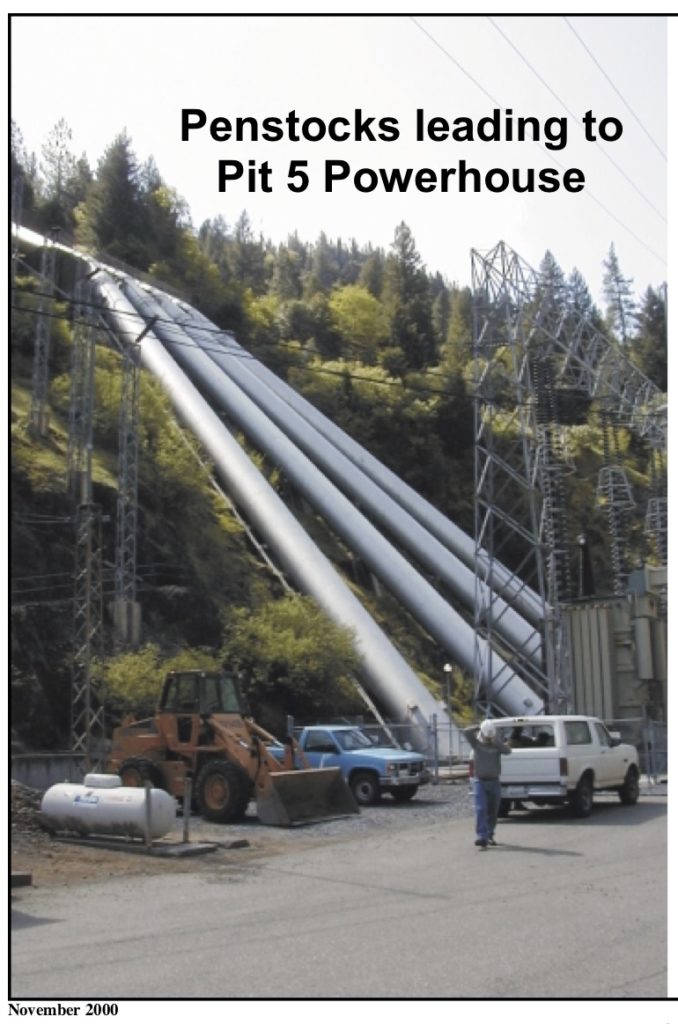

Thousands of cubic feet per second of river water is diverted from the sacred river into the first diversion tunnel, which drains down into the Tunnel Reservoir, which is just below and to the west of the dam. The water then drains out of the Tunnel Reservoir (down Tunnel #2) to the valve house above the powerhouse. The tunnels have a combined length of approximately 28,200 feet (more than 5.3 miles). Four steel penstocks (giant pipes), connect Tunnel No. 2 to the Pit 5 Powerhouse. They send the highly-pressurized water into the Pit 5 Power turbines with a total flow capacity of 3,580 CFS!

The powerhouse is a multi-level, concrete structure. Inside the powerhouse, the gravity-fed diverted river water rotates turbine blades, which spin generators that convert the mechanical energy of the spinning turbine into electrical energy. This electricity is sent through a huge infrastructure of overhead power lines, sub-stations, and transformers into California’s fragile, outdated, and dangerous electrical grid.

This outdated system could be replaced with increased energy efficiency, conservation, and localized solar and micro-hydropower systems that would not have such devastating effects on the watershed ecology. We need to get rid of this antiquated destructive large-scale dam system and repopulate the rivers and creeks with the anadromous fishes that are so important to the health of the riparian zones, the surrounding lands, and the wildlife and people in the precious habitats of the watershed!

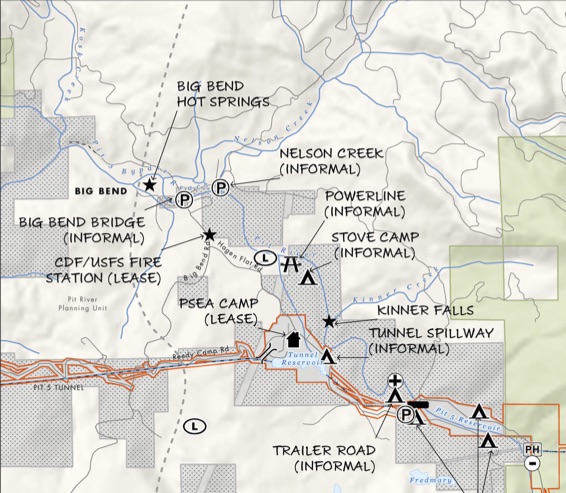

In addition to all the dams, reservoirs, tunnels, pipes, and powerhouses, PG&E owns huge tracts of land and water rights. They also maintain permanent employee housing and other storage facilities located at Pit 5 Powerhouse and Camp Pit (aka PSEA Camp), a 20-acre recreational facility located near the Pit 5 Tunnel Reservoir “open conduit”, which was converted from the 1940s dam and tunnel construction-era housing and is leased to the Pacific Gas and Electric Company Employee Association, for PG&E employee recreational use.

The numerous dams were conceived and built a century to a half century ago, when the scientists of the day knew so much less about the crucial importance of respecting and protecting watersheds and riparian ecosystems. Many negative results are still problematic today. The shortsighted river damming and diverting have tragically prevented the amazing salmon populations from making their journey home to countless inland habitats, including the largest one, which is the Pit River watershed, including the Madesi Valley where the majestic river twists through the Cascade Mountains.

This huge loss of one of the largest salmon runs in the world has been a devastating travesty for not only the salmon themselves, but for many interconnected parts of a healthy and thriving regenerative bioregion. Native American tribal traditions and nutritional resources were mindlessly and brutally terminated with the loss of the salmon runs. The riparian ecosystems, wildlife populations and diversity, soil and forest health, and the precious spiritual connections to the free-flowing rivers and salmon were hugely abundant before the dams were installed. All these life-giving components to a healthy world have been compromised, disrespected, and diminished as a result of this inappropriate technology.

Furthermore, the reservoirs formed by dams in rivers become stagnant pools where toxic algaes can grow, causing helth risks to people, pets, and aquatic organisms. These reservoirs also cause increased greenhouse gas emissions, as Methane is released from the stagnant water and drowned river bank flora.

These dams, powerhouses, and diversions are permitted under two operating licenses, “Pit 1” (FERC P-2687) and “Pit 3, 4, and 5” (FERC P-233). The hydroelectric projects are destructive to the Pit River watershed and ecosystems. The diversion of water out of long stretches of the river (called “reaches”) result in these sections having inadequate flows to maintain the healthy aquatic and riparian ecosystems that existed for many thousands of years prior to the damming and diverting. In the Pit 3, 4, and 5 developments, the tunnels are just over four or five miles long, respectively. This re-plumbing of the Pit River channels water around a combined 30 miles of natural riverbed. This is not an appropriate or acceptable way to make electricity and profits.

(photo from Library of Congress)

The Pit 4 Diversion Dam is important as an original feature of the Pit 3, 4 and 5 Hydroelectric Plant. Pit 4 Dam is an excellent example of early twentieth century hydroelectric architecture and represents the original aesthetic design characteristics of the overall Pit River system, while also unique and designed as a separate, individual feature. The system and the dam itself reflect a higher degree of architectural aesthetics than projects built in later years. Its impact on California has been significant and very harmful in several ways, helping to wipe out one of the world’s largest salmon runs and degrading the health of the river in general and the surrounding riparian forests.

The Pit River and many tributaries now run into Shasta Lake reservoir, and the stored water eventually flows into the Sacramento River, the San Francisco Bay, and the Pacific Ocean. The pristine McCloud River is one of the main tributaries, and flows from just north of Big Bend. A dam on the McCloud River diverts water to the Iron Canyon Reservoir, which is six miles above Big Bend. The diverted water is then is piped down to the James B. Black Powerhouse on the Pit River, just across the river from the Pit 5 Powerhouse, located below and downriver from the town of Big Bend.

- Completed 1965

- Named after the now deceased James B. Black, PG&E president for 20 years

- Uses McCloud River water from Iron Canyon Reservoir through an 8-mile-long 17-foot diameter tunnel and a one-mile-long penstock

But with profits and growth guiding these projects, the dams and power stations supported and encouraged the industrial development of Northern California and especially the San Francisco Bay Area. Electricity from the multiple rivers and dams that flow into Shasta Lake have powered the economic and developmental growth of the state, but at what cost? Despite the profits made and the convenient source of electricity without burning fossil fuels or adding more nuclear plants, these remote hydropower systems have had far-reaching negative effects as well, and they continue to remind us of a time when the river ran free and wild, and the watershed was much healthier and had more plentiful natural resources.

Gradually Improving Systems Built With Ignorance and Arrogance:

By the time the Pit 1 operating license expired in 1995, PG&E had very few environmental requirements. The Pit 1 forebay, only 12 to 15 feet deep, fluctuated as much as 3 feet per day in response to power demand. No minimum flows were required in any project reaches, leaving over 8 miles of the Fall and Pit Rivers dewatered and river levels downstream from the powerhouse highly unstable.

As required by the new Pit 1 license issued in 2003, PG&E releases steady water into the Pit River Canyon, and new release rates for the powerhouse slowed unpredictable fluctuations and curbed streamside erosion downstream. Punctuated flushing flows control unwanted vegetation from encroaching into the river channel and serve a dual benefit as a special whitewater release in the summer, and fall whitewater flows were implemented in 2011. For the first eighty years, the project had operated with no flow requirements. Since 2003, thanks to the new license, there is more balance.

When the Pit 3, 4, and 5 license was set to expire, PG&E was pressured into joining a new collaborative planning and dam/diversion modification strategy: convene negotiations with more stakeholders and create an agreement to settle principal issues to reduce the huge corporation’s greedy prioritizing of profits over the health of the environment and wildlife, in addition to recreational uses. Convened in 1998, the Pit River Collaborative Team (PRCT) finally produced a settlement in 2003 that formed the framework of the new 2007 license. The license term – 36 years – is set to end at the same time as the Pit 1 license, for maximum coordination of the Pit River.

Several interests directed the 2007 licensing agreement:

-Bring water back into 22.5 miles of the Pit closer to naturalized rates (but still a small fraction of pre-dam flows).

-Enhance the top trout fishery in the Pit and in Hat Creek.

-Ensure that recreational resources- including fishing, whitewater, and the Pacific Crest Trail – are protected (but with only minimal improvements and regulation oversight)

The 2007 PRCT agreement established new minimum flows at double or more the previous minimums. It also prescribed seasonal variation and a 0.5 foot-per-hour rate of change in releasing the flows, to mimic a natural hydrograph. These renewed flows and key habitat enhancements such as gravel replenishment and transporting wood downstream from the reservoirs will improve conditions for fish and other wildlife.

Under this agreement, PG&E (like a fox guarding a hen house) has inappropriately been allowed/assigned to manage the sensitive task of ongoing monitoring of aquatic life and water quality extensively over the 36-year duration of the license, guiding adaptive management decisions for the river. This arrangement constitutes a blatant conflict of interest. PG&E’s dismal record of inadequate historic mistreatment of the river and the interconnected ecosystems in the watershed makes their monitoring, reporting, and even some self-regulation designations highly inappropriate.

Hat Creek Protection Efforts:

Through the settlement talks, key parties also resolved protection of the Hat Creek Wild Trout Management Area. Established in 1969, the Area is the first state-designated Wild Trout Creek. At the base of its 3.5 mile length, the state constructed a barrier dam to prevent the warm-water fishery of Lake Britton from invading the prized cold-water trout fishery. A separate 2003 agreement, partially incorporated into the license, commits PG&E to funding 50% of the costs to maintain the barrier dam, and to providing a measly $300,000 toward stewardship management over the next 30 years (2007-2037).

Relicensing Documents for Pit 3, 4, and 5 are available for reading online…

RELICENSING IMPROVEMENT CLAIMS:

• Increased flows to over 22 miles of bypassed river by 2 to 20 times more than the previous minimum levels, balancing fishery restoration with access and angling

• 0.5 foot/hour is the maximum rate of change in water releases, similar to the natural rate of streamflow recession

• A minimum of 624 tons of gravel placed annually in bypassed river reaches to replenish eroded habitat

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Improvements to Pit River Dams in 2008 (& Pit 5 Dam floodgates in 2017).

2008 Project Details: As the Pit River flows out of Northern California’s Lake Britton, it first begins its journey to Lake Shasta through a 30-mile scenic watershed divided into five segments, or reaches, each created by a dam. The 2008 project entailed installing an 8-foot-diameter pipe and appurtenances through Dams 3, 4 and 5 to increase the river’s flow as part of a relicensing agreement with the Federal Energy Regulatory Commission. Penetration of each dam involved coffer damming, core drilling, and demolition, as well as structural analysis of the penetration itself. Collaboration between the Owner, Designers, and Contractors resulted in various value engineering opportunities.

Installing the 30-foot-tall structural steel intakes and custom-made knife gate valves required work on the water and diving depths up to 100 feet deep. The project began in Spring 2008, working on the design with Devine Tarbell & Associates. Valvehouse construction required soil nails and rock bolts during foundation excavation, drilling 30 to 70 into the hillside, as well as shotcrete support walls. In addition to the flow modifications, the project added 38 turnouts to the existing River Road, replacement of two bridges, drainage system upgrade, and recreation improvements throughout the Pit River watershed, including adding the Madesi Campground and River Acess near the Pit 5 Dam in Big Bend. All of this work took place in a highly sensitive environment, allegedly “under close scrutiny by regulatory agencies”.

2008 Project Highlights:

- Installation of new intake structures in front of two existing dams and installing gates within existing spill gates requiring marine construction

- Coring through existing concrete dams

- Large-diameter pipe (8 ft.) installation through these existing dams

- 10,000 LF of rock bolts, 10 to 60 ft. in length for excavation support

- Construction in environmentally sensitive, scenic waterway (??)

- Critical permitting

- Environmental mitigation (??)

- Groundwater treatment

- Traffic control

- Noise and dust mitigation

2012 Action News: On Thursday, August 9th, 2012, American Whitewater and Friends of the River notified the Federal Energy Regulatory Commission, U.S. Fish and Wildlife Service, and PG&E of their intent to sue for violations of the Endangered Species Act at the Pit 1 and Hat Creek Hydroelectric Projects in California. The projects have numerous impacts on the endangered Shasta crayfish and have been in violation of the Endangered Species Act since 2005.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~Shasta Dam- THE BIG ONE!

When all the dams on the Pit River and the McCloud River are removed some day, the salmon populations will still not be able to get back home unless the HUGE Shasta Dam is also removed and/or some kind of effective new fish ladder is invented and installed. At this point, there is no known practical way to get the salmon past this monstrosity of a dam.

The Shasta Dam Construction started in 1937 and provided thousands of jobs. It was completed in 1945, and was the second-tallest in the United States after Hoover Dam, and was considered one of the greatest engineering feats of all time.